The Glass Perfume Bottle Production Process

The Glass Bottle Production Process

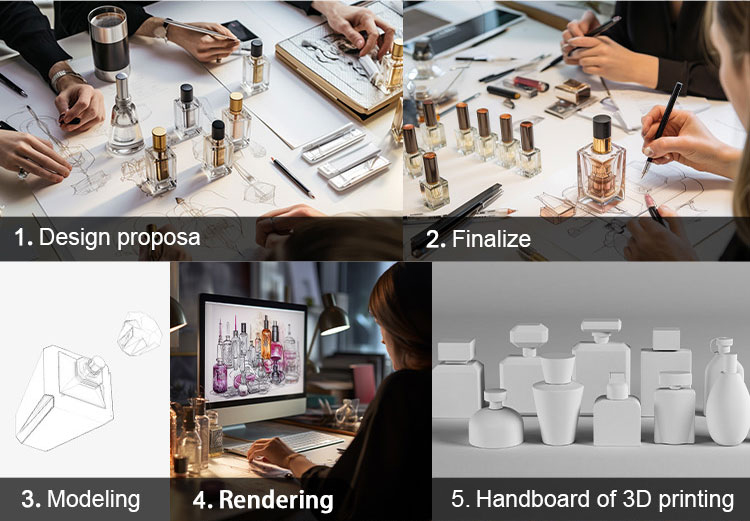

The Design Process

1. Design Proposal

Our designers work closely with clients to understand the brief and develop concept sketches.

2. Finalize

A final design is chosen based on brand vision, target market and feasibility for manufacturing.

Mold Making

3. Modeling

A 3D digital model is created from the finalized drawings and specs.

4. Rendering

Detailed renders and prototypes help visualize the final bottle.

5. Handboard/3D Printing

Small handboard models or 3D prints are produced for client approval.

6. Molding

Molds are machined from the final 3D model using CNC or cast from prototypes.

Production

7. Molding

Molds are used to shape molten glass into bottles through automatic production.

8. Prototyping

Preproduction samples are checked for quality, precision and client approval.

Finishing

9. Prototyping

Any modifications to the mold or process are made based on prototyping feedback.

10. Final Bottle

Bottles are decoratively finished, marked and packaged ready for distribution.

Through this proven process, we effectively translate creative visions into high quality, precisely produced perfume glass bottles and containers for our clients.

- PREV : Dongguan Kuulee Glass Packaging Showcases Innovative Perfume Bottle Designs at Shanghai Beauty Expo

- NEXT : It's the end one!

HOME

HOME